- Telephone

- Email

National Pump & Energy (NPE) has not only one of the largest ranges of specialised equipment, but also the most qualified professionals in pumping and power generation in Australia. Basically, when it comes to pumping, power generation and compressed air equipment, NPE are your total solutions partner. We offer tailored solutions and service. Our personal and detail oriented approach, means you can be assured all project requirements will be met. Below are some examples of our extensive experience across the construction, mining, oil & gas, municipal, agricultural and industrial industries.

Wellpoint dewatering for a civil contractor installing underground services.

Read More

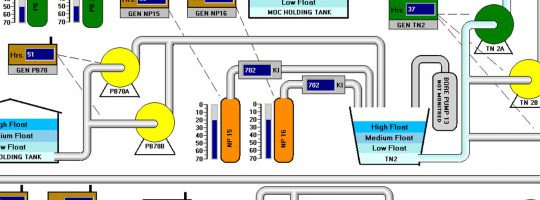

NPE optimised water management operations at BC Iron’s Nullagine site, with autonomous water transfer station, transferring critical data to the desktop.

Read More

NPE prepared a site-wide wireless network for a Western Australian mine site, which enabled monitoring of water management assets and monthly reporting of key data.

Read More

NPE provided an innovative power generation solution for Consolidated Minerals Ltd Woodie Woodie site in Western Australia.

Read More

Remote standpipe fully automated power supply to submersible pump, for filling water carts, at the Woodie Woodie site in Western Australia.

Read More

NPE provided a continuous, remote power supply mill return water system to the Woodie Woodie site in Western Australia.

Read More

NPE designed, supplied, installed and maintained a 2mw power generation station for various facilities at the detention centre, in Derby, Western Australia.

Read More

NPE designed, constructed, installed and maintained a 2mw power generation station for site camp facilities at BC Iron – Nullagine, Pilbara, Western Australia.

Read More

NPE provided power for temporary sea water transfer for pond zero, at Rio Tinto’s Dampier Salt Limited.

Read More

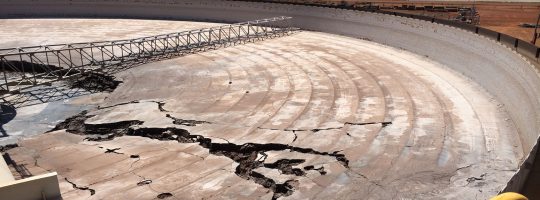

NPE was contracted to de-scale the slipped and unstable material at the Mount Gibson Iron Tallering Peak site, in Western Australia.

Read More

NPE provided a complete pond clean service using a highly trained crew to carry out the task, at the Barrick Gold Granny Smith Gold Mine, Western Australia.

Read More

NPE provided a complete thickener clean for Goldfields St Ives Gold Mine, utilising the hydromining method, using a highly trained crew to carry out the task.

Read More

NPE were engaged to supply a turnkey solution for the removal of settled silts.

Read More

NPE provided specialist hydromining services to the Kalgoorlie Consolidated Gold Mine, to remove tailings slimes from secondary settling dam. Tailings slurry was pumped back into primary settling dam.

Read More

NPE supplied a fully integrated system allowing for dust suppression compliance on the COS of one of the world’s largest gold mines.

Read More

NPE worked with Chevron Australia on their specialised offshore pumping requirements and tunnel boring machine TBM recovery, commissioned for the Wheatstone LNG trunkline installation in Western Australia.

Read More

Client required return of their clarified water tank to clean state in critical time frame.

Read More

Remove several years of built up mud in the main water supply dam of the bauxite wash plant.

Read More

Comprehensive hydromining package to clean Citic’s 90 metre tails thickener tank.

Read More

Removal of several years of built up material in the main process water and thickener feed tanks of the processing plant in order to gain capacity in the tanks.

Read More

Provide water winning and high pressure, high volume booster pumps for offshore heat suppression system, to be used at various offshore locations across Asia.

Read More

Decommissioning of 2 x FPSO process systems and subsea pipelines in the Timor Sea.

Read More

Complete operational pre-commissioning pumping system to supply filtered, treated water to pig launcher at 300lt/sec and 25bar at Bayu Undan Gas Pipeline.

Read More

Design, engineer, construct, certify and operate water winning and pigging pump package – 615m3/hr to 32bar

Read More

Supply fully automated diesel powered assisted evaporation system.

Read More

Supply fully automated diesel powered accelerated evaporation system.

Read More

Provide a ‘safe’ and effective evaporation system to disperse waste water.

Read More

Supply fully automated self-managed diesel powered high head high flow suction lift pumping system.

Read More

Installation of 42km pipe work, refurbish existing pump station and installation of new pump station.

Read More

Comprehensive de-scaling via high pressure water cannon was undertaken, enabling a safe and stable area for a ventilation portal to be installed.

Read More

Supply and installation of a staged dewatering pipeline for the disposal of saline water back into the aquifer.

Read More

Installation of Raw Water Overland Pipeline and Borefield Infrastructure.

Read More

Design, engineer, install and commission purpose built direct drive diesel pumping system including multiple pontoon units, to deliver complete dewatering system and services.

Read More

This was a multi-faceted project and scope of works, completed by NPE on behalf of the client, BHP Billiton, at their Yandi Mine Site in Western Australia.

Read More

The client had a significant build-up of solids in their process area run-off pond. They needed it removed.

Read More

The task was to provide temporary pit dewatering services, using pontoon pump system and booster pumps, at Higginsville, in the Goldfields Western Australia.

Read More

The requirement of this project was to design and supply fully automated diesel powered high flow pumping system to a duty of 720lt/sec @ 120m tdh.

Read More

NPE provided power for temporary sea water transfer for pond zero at Dampier Salt Limited in Western Australia.

Read More

Our requirement was to design and supply fully automated diesel powered high flow pumping system to pump a combined duty of 800lt/sec @ 80m. We delivered on brief.

Read More© National Pump & Energy 2024