The air-driven high-pressure pumps used in the chemical injection unit are particularly built for maximum performance and efficiency. The device has been developed for both on and offshore operations and is housed in 316 Stainless Steel trolley for portability. Pumps are suitable for various media including water, oils, chemicals. Some of the applications in the chemical and Offshore industries are injection of inhibitors such as methanol and glycol in wells, injection of coolants, charging hydraulic accumulators, actuation of subsea valves, pipeline testing, Hydro testing, etc. A chemical injection unit injects a precise amount of specific chemicals into a system at the proper temperatures, pressures, and flowrates. A chemical injection unit consists of a chemical dosing pump, instruments, piping, valves, 4L calibration column, stroke counter and a trolley mounted construction.

KEY FEATURES

- Durable, High-Quality materials

- Long stroke, single drive double acting pump

- Accurate and Repeatable Injection

- Quick Maintenance and Low Downtime

- Stall feature / Pressure maintained without energy consumption – Suitable for hydro testing

- Explosion proof, no electrical power required

- Air filter regulator valve

- Stroke Counter

- Pressure Gauge (Optional - Calibrated)

- PRV 1000-4375 psi (Optional NATA recert)

- Lift, Protection Cage with MO32 certifications (optional)

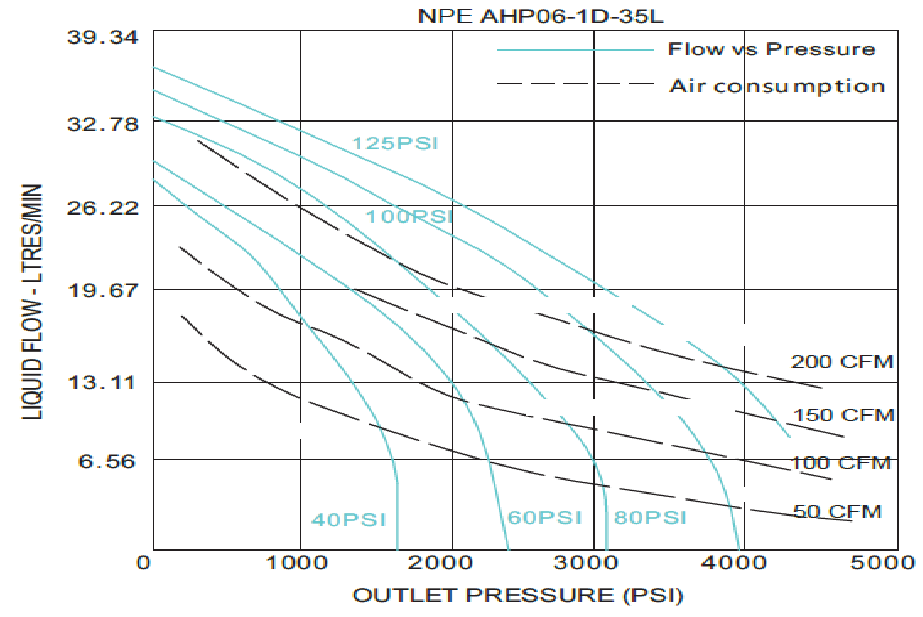

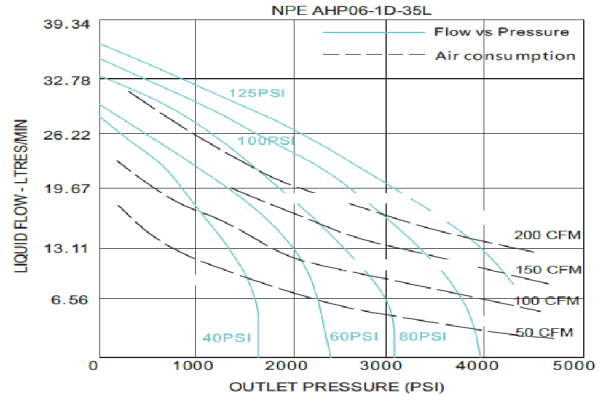

PUMP PERFORMANCE CURVE

| GENERAL SPECIFICATIONS | |

|---|---|

| Air drive pressure | 1-10 bar/14.5-145 psi |

| Calculated outlet pressure at 10 bar/145 psi air supply | 600 bar / 8,700 psi |

| Pressure ratio | 1:66 |

| Displacement volume / double stroke | 65 cm³ / 3.97 cub. inch |

| MATERIALS OF CONSTRUCTION | |

|---|---|

| Pump Body | Stainless steel (17-4-PH) |

| Piston | Stainless steel (17-4-PH) |

| Seal package | UHMWPE (ultra-high molecular weight polyethylene) / FKM |

| Materials of Construction | |

|---|---|

| Pump Body | Stainless Steel (17-4-PH) |

| Piston | Stainless Steel (17-4-PH) |

| Seal Package | UHMWPE (Ultra-High Molecular Weight Polyethylene) / FKM |